Reaction Chamber

The main function of the reactor chamber is to isolate the reaction from the general operating environment. The chamber must contain the extreme heat and radioactivity resulting from the reaction and maintain the vacuum necessary for reaction operation.

While the radiated heat from the reaction plasma is significantly less than the temperature of the plasma itself (around 150 million degrees), the facing surfaces of the reactor chamber need to withstand several thousand degree temperatures and bombardment from high energy particles escaping the reaction plasma.

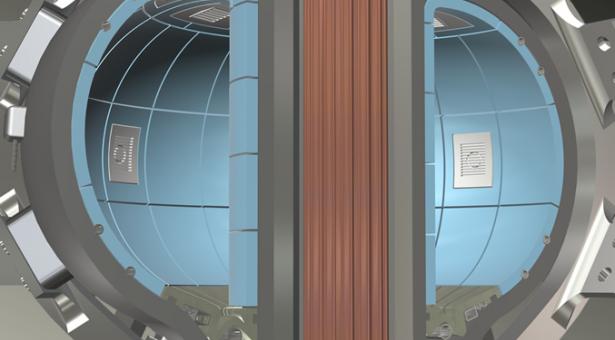

The reactor wall acts as a safety containment barrier and allows a vacuum to be maintained within the reaction chamber. The reactor chamber is toroidal in shape with a double-wall design constructed from stainless steel.

Passages between the layers allow cooling water to circulate, keeping the chamber wall cooled to approximately 250 degrees centigrade. A series of ports through the reactor wall provide access for remote handling operations, monitoring, heating and vacuum systems.

In order to ensure the reaction chamber meets a service life requirement of 10-15 years, significant shielding is added to the interior surface to protect it from the reaction.

Reaction Isolation Shield

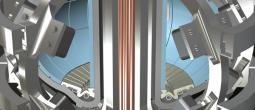

The chamber wall is lined with a system of modular, dual-layered components referred to as the Reaction Isolation Shield (RIS). The system is designed to remove the bulk of heat and radiation from the reaction before it reaches the chamber wall. The severity of the conditions facing the reaction limits the service life of the components and so the modular design allows for their replacement as required without interrupting reactor operation.

The chamber wall is lined with a system of modular, dual-layered components referred to as the Reaction Isolation Shield (RIS). The system is designed to remove the bulk of heat and radiation from the reaction before it reaches the chamber wall. The severity of the conditions facing the reaction limits the service life of the components and so the modular design allows for their replacement as required without interrupting reactor operation.

The outer layer directly facing the reaction is designed to remove the bulk of the reaction’s heat load. This layer is constructed from beryllium, which has excellent thermal conductivity and is particularly stable under thermal loading. Because of its low density and atomic mass, beryllium is relatively transparent to ionizing radiation which allows the high-energy neutronic particles produced by the reaction to pass through the modules with minimal impact.

The inner layer is designed to remove the bulk of the radiation load from the reaction. This layer is constructed from a vanadium-tungsten alloy chosen for its durability. The alloy has a low diffusive index for high-energy particles making it ideal for containment purposes. The alloy also has a moderate thermal neutron-capture profile, reducing neutronic activation, which alters the physical characteristics of the material and accelerates degradation. The isotopes produced by the neutronic activation of the alloy have a short half-life, reducing the complexity of waste material handling.

Tritium Breeding Modules

The scarcity of tritium requires fuel production techniques to ensure adequate supply. Tritium breeding techniques will be used within the reactor to produce fuel.

Dedicated RIS modules will incorporate lithium, which interacts with high-energy neutrons like those from the reaction to produce tritium. This process is referred to as tritium breeding. The modules will incorporate systems to extract the tritium for use as reactor fuel.

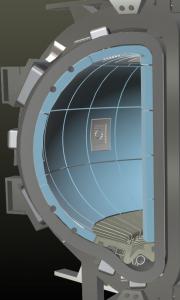

Divertor

The divertor is strategically placed at the bottom of the reaction chamber where the bulk of the reaction’s high-energy particles are diverted (hence the name) by the magnetic containment system. The divertor extracts heat, helium ash (a by-product of the reaction) and plasma impurities from the reaction chamber. The primary coolant system runs through the divertor to draw heat away from the reactor chamber for transfer to the generating turbine system.

A modular design allows components to be replaced remotely without interrupting reactor operations. Each module has three targets (the inner and outer vertical targets and the dome) that are struck by high-energy particles from the reaction, while exhaust ash falls between the targets into extraction vents. The targets are situated at the intersection of field lines from the magnetic containment system and are composed of the same vanadium-tungsten alloy as the inner layer of the RIS modules.

The divertor’s supporting framework is constructed of stainless steel.

Diagnostic Monitoring

The importance of the reactor’s shield components requires constant monitoring. The health of reaction-facing components is monitored using micro-electrical resistance tomography which allows the imaging of sub-surface structures from electrical resistivity measurements conducted using electrodes inserted into modules. This allows the effects of neutronic activation on components to be continuously monitored, allowing identification of components requiring replacement.

Neutronic activation is caused when one of the high-energy neutrons escaping the reaction is captured by a nucleus within the material making up the module. This combination creates an isotope, thereby changing the physical characteristics of that part of the module. These changes reduce the module’s strength and cause an increase in the module’s high-energy particle diffusive index, diminishing its capacity to shield against radiation.

Reactor Vacuum

The reaction chamber must be maintained in a high vacuum to prevent non-charged particles (which can pass through the magnetic containment field) contaminating the reaction plasma. The status of the vacuum is measured in Pascals (Pa) using an ionisation gauge. Range 1×10−1 to 1×10−7.